ASTM A790无缝和焊接双相钢管的重量、外径和壁厚公差

该公差来源于ASTM A999 合金和不锈钢钢通用要求

ASTM A999 General Requirements for Alloy and Stainless Steel Pipe

9 Permissible Variation in Mass for Seamless Pipe

9.1 Except as allowed by 9.2, the mass of any length of seamless pipe in sizes NPS 12 and smaller shall not vary more than 10 % over or more than 3.5 % under that specified. For pipe in sizes larger than NPS 12, the mass of any length of pipe shall not vary more than 10 % over or more than 5 % under that specified. Unless otherwise specified, the mass of lengths of pipe in sizes NPS 4 and smaller shall be determined separately or in convenient lots; the mass of lengths of pipe in sizes larger than NPS 4 shall be determined separately.

9.2 Minimum Wall—If the wall thickness of the pipe is specified as minimum wall in the purchase order, the mass of any length of seamless pipe shall not vary more than 16 % over that calculated in accordance with 14.3. Unless otherwise specified, the mass of pipe in sizes NPS 4 and smaller shall be determined separately or in convenient lots; the mass of pipe in sizes larger than NPS 4 shall be determined separately.

10 Permissible Variations in Wall Thickness

10.1 Seamless and Welded—Except as required by 10.1.1, the minimum wall thickness at any point shall not be more than12.5 % under the nominal wall thickness specified.

10.1.1 Minimum Wall—If the wall thickness of the pipe is specified as minimum wall in the purchase order, there shall be no variation under the specified wall thickness.

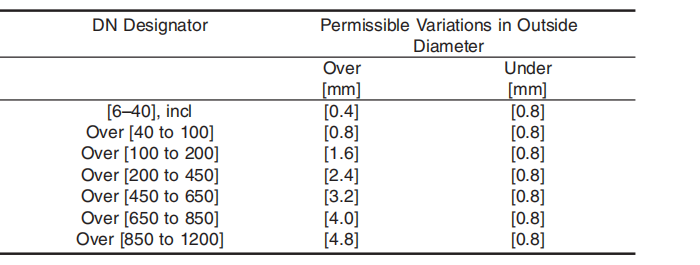

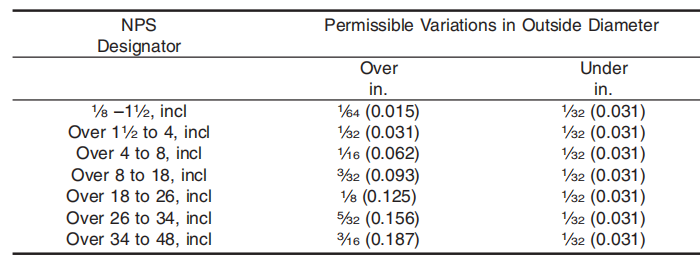

12 Permissible Variation in Outside Diameter

12.1 Variations in outside diameter, unless otherwise agreed upon, shall not exceed the limits given in Table 1. The tolerances for outside diameter include ovality, except as provided for in 12.2 and 12.2.1. (See Note 2.)

12.2 For thin-wall pipe, defined as pipe having a wall thickness of 3 % or less of the specified outside diameter, the diameter tolerance of Table 1 is applicable only to the mean of the extreme (maximum and minimum) outside diameter readings in any one cross-section.

12.2.1 For thin-wall pipe, the difference in extreme outside readings (ovality) in any one cross-section shall not exceed 1.5 % of the specified outside diameter.

NOTE 2—Thin-wall pipe usually develops significant ovality (out-of roundness) during final annealing, straightening, or both. The diameter tolerances given in Table 1 are usually not sufficient to provide for additional ovality expected in thin-wall pipe.